NON-VENTED HELMETS: THE STANDARD OR ELECTRICAL WORK

Every year, thousands of workers suffer electrical injuries, with many incidents resulting in severe burns, long-term health effects, or fatalities. Since electrical hazards all vary by job and their environment, different helmet classes were developed to provide the proper level of protection. These classes are:

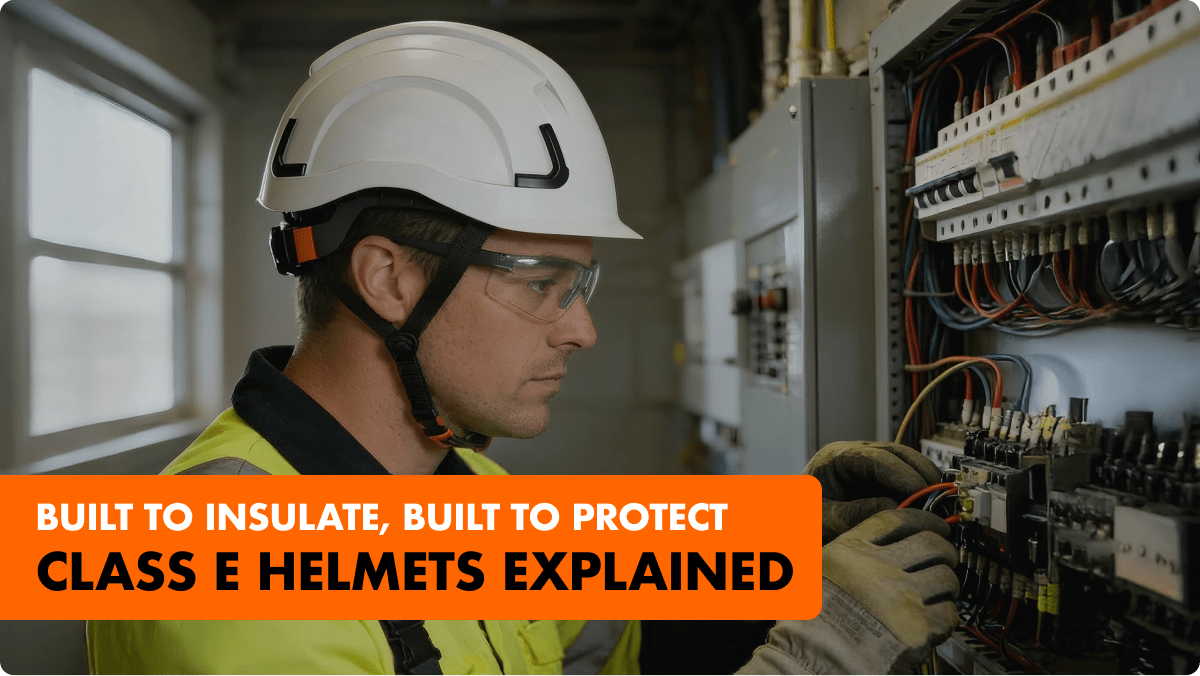

Class E helmets are built specifically for high-risk electrical environments. They were developed in response to the real dangers faced by workers in electrical, utility and industrial environments.

One of the most important features of a Class E helmet is its non-vented design. While ventilation can improve airflow, small openings in a helmet can allow electrical current to pass through. By using a fully sealed shell, Class E helmets help maintain electrical insulation across the entire helmet, reducing the chance that electrical contact reaches the wearer’s head.

WHAT OSHA AND LABOR DATA REVEAL ABOUT ELECTRICAL HAZARDS

According to OSHA and BLS, electrical shock and electrocution remain among the most serious hazards in construction and industrial work. Contact with electricity is one of the leading causes of fatalities in the workplace.

OSHA requires employers to conduct hazard assessments and provide appropriate PPE when electrical risks are present. When head protection is part of that assessment, the helmet’s electrical rating becomes critical not optional.

WHY CLASS E HELMETS ARE THE BETTER SOLUTION

Today, non-vented safety helmets are split into two electrical classes: Class G (low voltage) and Class E (high voltage). On paper, this makes sense because different electrical risks call for different levels of protection.

Today, non-vented safety helmets are split into two electrical classes: Class G (low voltage) and Class E (high voltage). On paper, this makes sense because different electrical risks call for different levels of protection.

However, real job sites rarely stay that simple. Most workers are contractors who move between tasks, trades, and locations during the same day. They may work near electrical hazards at one job and then switch to tasks with no electrical work at all. They also face other risks, including falling objects and side impacts, which has pushed many sites toward stronger Type II helmets with chin straps.

In the past, there were good reasons to keep Class G and Class E separate. Class G helmets were usually lighter, cooler, and cheaper, which made them more comfortable for trades that did not work around high voltage. Class E helmets offered more protection but often added heat and weight.

But new helmet designs are closing that gap. Modern Class E Type II helmets can now offer high-voltage protection without giving up comfort or breathability. For example, the H2-EH uses internal channels in the foam to let heat escape, keeping the worker cool even without shell vents. As these differences shrink, having two separate electrical classes becomes harder to justify for many environments.

This does not mean the standards are wrong. They were made to protect workers and have done so for years. But job sites are more dynamic now, and helmet technology has evolved. The industry appears to be moving toward a future where the worker can rely on one helmet across tasks, instead of switching helmets based on each scenario.

DEFENDER SAFETY DEVELOPING VOLTFENSE™ TECHNOLOGY

Many helmets on the market meet the minimum requirements but fall short in consistency, durability or long-term performance. In some cases, materials or design shortcuts can compromise electrical resistance over time.

At Defender Safety, we developed VOLTFENSE™ technology to fill in those gaps. The result is a helmet that doesn’t just meet the standards but goes above and beyond them. Our patented design creates a lifetime barrier between the outside of the helmet and the suspension reducing the electrical risk exponentially.

With all of our helmets it is guaranteed that your gear is third-party tested and ensures your helmets meet and exceed strict industry standards, verified by independent labs and not internal marketing. Here at Defender Safety we believe it’s not just about what a company claims but what’s been proven. We want to do everything we can to help employers and workers make informed decisions while protecting lives with gear that actually performs.

With all of our helmets it is guaranteed that your gear is third-party tested and ensures your helmets meet and exceed strict industry standards, verified by independent labs and not internal marketing. Here at Defender Safety we believe it’s not just about what a company claims but what’s been proven. We want to do everything we can to help employers and workers make informed decisions while protecting lives with gear that actually performs.

WHY DEFENDER SAFETY IS THE LEADING CHOICE IN SAFETY IN 2026

If you haven’t upgraded your crew to Defender safety helmets yet, now is the time. Designed for maximum protection some key features of our helmets are:

CUSTOMIZING YOUR DEFENDER SAFETY HELMET

And because every job site — and every team — is different, Defender Safety helmets can be fully customized to meet

your needs.

Ready to protect your team with helmets backed by real testing?