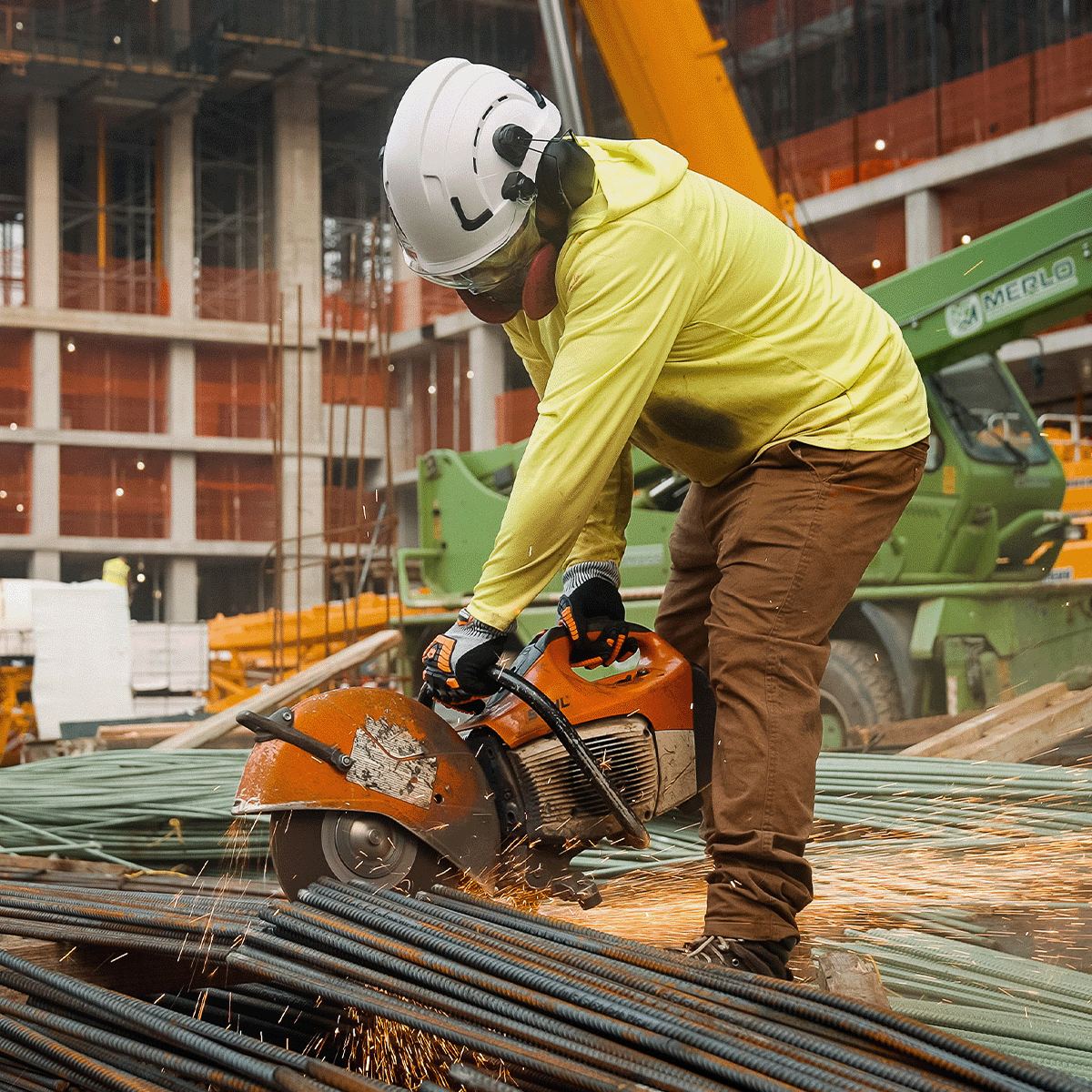

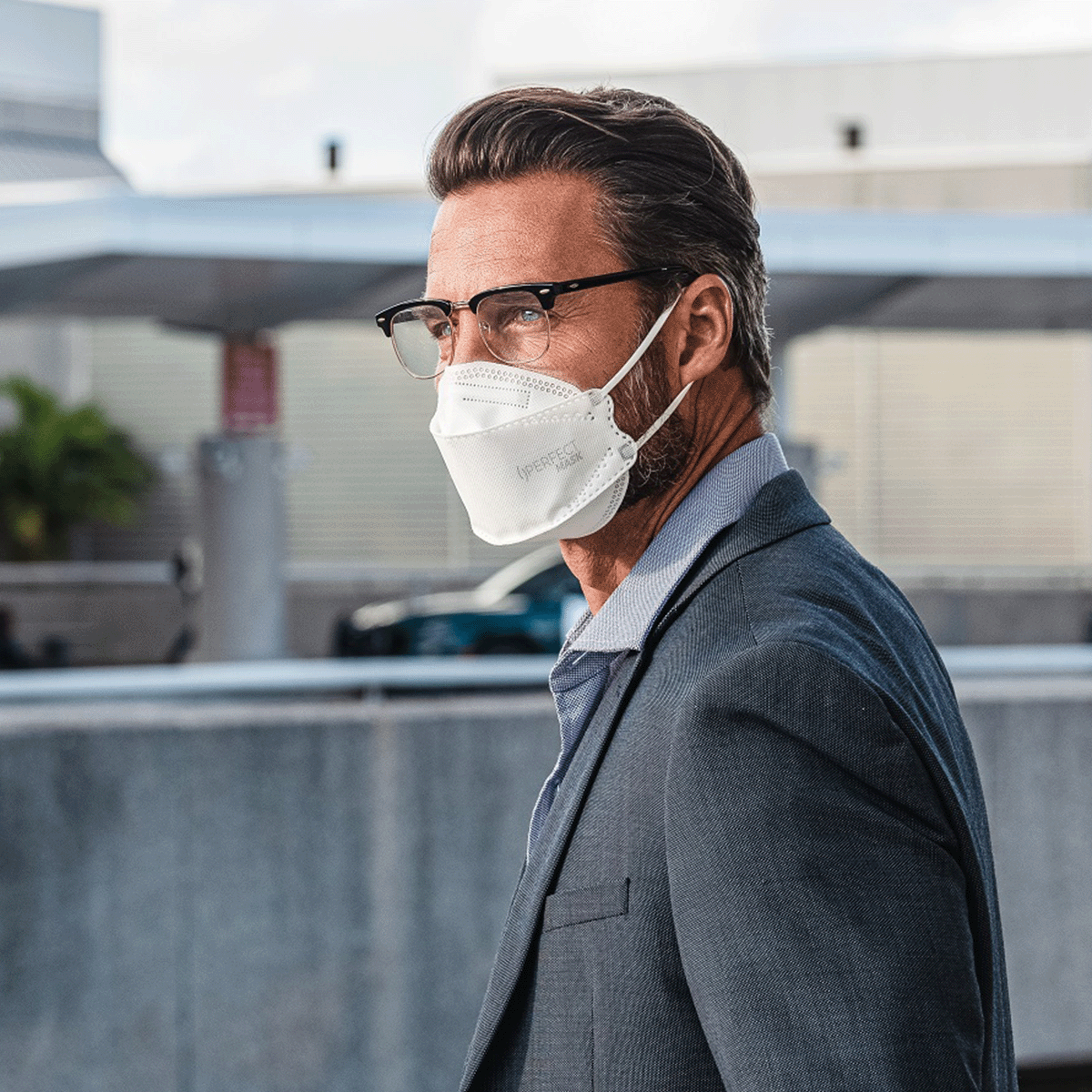

Over the course of the pandemic, the global manufacturing industry has experienced an unprecedented surge in demand for large volumes of personal protective equipment (PPE) including face masks, gowns, and nitrile gloves.

At the onset of COVID-19 in early 2020, the U.S. federal government’s Strategic National Stockpile contained only 1% of the 3.5 billion masks that would be needed within the first year of the pandemic. With more than 60% of the world’s PPE made in Malaysia and the majority of the remaining supplies coming from Thailand and China, the U.S. and its healthcare industry found itself in a highly unstable sourcing environment, overwhelmingly dependent on other countries for PPE.

Shortages ensued, and pandemic demand led countless manufacturers to redirect existing resources into PPE development and expand domestic production capacity for much-needed supplies. As a New York-based company that took part in this rapid mobilization, we’ll dive into why continuing to build U.S. PPE manufacturing capacity well beyond this health crisis is critical, as well as the benefits of treating PPE safety stock as a budget essential in the coming years.

The State of PPE Manufacturing

Even as domestic production has improved, the pace has not kept the U.S. from continuing to experience shortages well over a year since the first COVID-19 cases began to surge. The issues facing our supply chain like international dependency well predate the pandemic, which has merely exacerbated these vulnerabilities.

In January and February 2020--during the height of the COVID-19 outbreak in Asia--the Chinese government organized a large-scale purchase of PPE on the global market to meet its own pressing demand, ultimately depleting supplies in the U.S. and other countries. As a result, when the U.S. began to have its own surge in demand, the cost of PPE began to skyrocket, with costs surging up more than 1,000% by April. Numerous states began calling for additional federal aid to procure supplies and streamline distribution, as healthcare systems struggled financially, facing rising hospitalizations and COVID-related revenue cuts.

By late spring over 80 different countries had taken steps to restrict or ban the export of face masks, protective gear, gloves and other goods in order to support their own pandemic relief efforts, which severely exacerbated U.S. shortages.

Much of this impact emerges from U.S. reliance on foreign channels - for example, an estimated 90% of N95 masks alone are imported. A more diverse portfolio of suppliers could better insulate the U.S. market from similar decisions made by China and other countries in the future, as well as from potential supply chain disruptions like this month’s ship blockage in the Suez Canal. Prioritizing domestic production will be one key part of that diversification process.

As of February 2021, frontline workers in 44 states are still experiencing shortages of necessary protective equipment, and of those, 35% reported that their facility had no supply remaining.

Potential Solutions Moving Forward

As we continue to weather the pandemic, efforts to limit the extent of our dependence on overseas production and actively diversify available PPE channels will be a long term endeavor.

In the interim, there are no easy solutions. As non-profits like Get Us PPE work to meet demand and the federal government weighs a range of policy tools, stockpiling may be a worthwhile immediate option for some facilities to consider.

In recent years, the healthcare system has taken on a cost-efficient, lean approach to its supply chain limiting redundancies that, while less cost-effective in the short term, are incredibly important once supplies become scarce. Some of the hardest hit hospitals this past year were reliant on a small number of vendors--so when PPE backorders accumulated, there was a forced scramble for alternatives.

By making stockpiling an essential piece of their budgets, healthcare systems can build more resilience into supply channels, to ensure that when a new spike arises, upstream supply disruption will have a less immediate effect.